Português

Português English

English

Languages

Hydro Paragominas - bauxite mine.

The bauxite mine visited during the field trip is located approximately 70 kilometers from Paragominas in northeastern Pará. The mine is jointly owned by the Norwegian company Hydro (67.9%) and Vale SA (32.1%) a Brazilian multinational metals, mining and logistics corporation. Brazil is Hydro's main source of the important raw material bauxite and is the country where the company has the most employees.

Although the motive for the trip was to see how the company restores the land that has been mined, it is perhaps interesting to learn a little about the bauxite mining operation itself and the ore's transformation into aluminium.

Bauxite is the most important of the aluminium ores containing 30-36% aluminium oxide (alumina). It is almost always found near the surface and can be strip mined with little or no overburden.

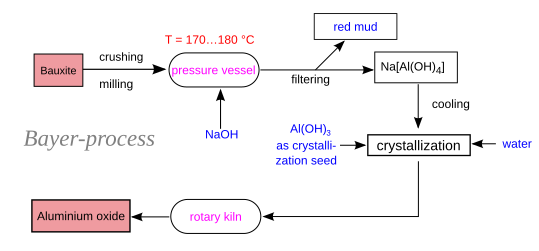

After extraction, the bauxite is washed and crushed (a process known as milling) to a size that is suitable for refining and mixed with sodium hydroxide to make a pump-able slurry. The alumina is formed by the Bayer process where the ore is heated under pressure with sodium hydroxide at a temperature of approximately 180oC. The reaction product is filtered to remove a red mud and then crystallized and heated in a rotary kiln to produce the aluminium oxide.

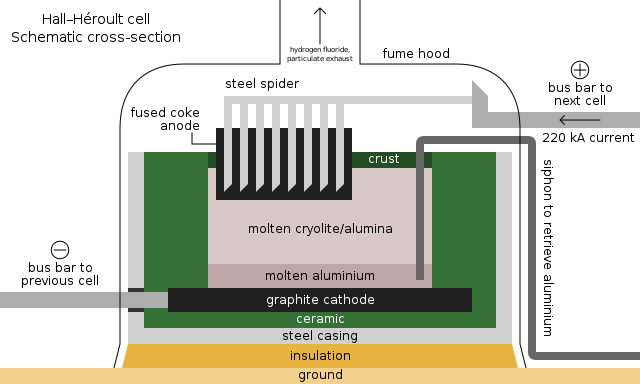

The aluminium oxide is smelted using the Hall–Héroult process where the alumina is first dissolved in a synthetic cryolite flux to reduce the operating temperature and subsequently electrolysed at a temperature of 940-980oC to produce almost pure aluminium.

By Parcly Taxel - Own work, CC BY-SA 4.0

In Brazil, raw materials are extracted at Paragominas and Trombetas and the bauxite is refined to alumina (aluminium oxide) at the world's largest alumina refinery, Alunorte in Barcarena. 460,000 tonnes of aluminium metal are refined annually at the partly owned Albras plant.

Mining began at the bauxite quarry in Paragominas in 2007 where the ore is crushed and transported in a 244 kilometer-long pipeline to Barcarena, the location of the Alunorte aluminia refinery. 9.9 million tonnes of bauxite are extracted from 15.2 tonnes or ore each year and the current deposits have an estimated lifetime of a little more than 40 years.

The reforestation program commenced in 2009.

Hydro's collaborative biodiversity research project.

Normally, the bauxite is covered by a layer of rocks and clay, which is removed so that the bauxite can be extracted. This results in a mud that is deposited in settlement ponds which are later covered and planted to restore the natural vegetation of the site. Although most of the area being mined had been affected by logging, ranching and farming Hydro`s ambition is to return the already altered areas back to a better condition than before they arrived.The research related to the restoration of biodiversity is looking at soil quality and biomass and tests different restoration methods. Another project is looking at CO2 and methane releases and a third is examining Mycorrhiza, a fungus that symbiotically provides water and nutrition to trees.

One of the restoration techniques being studied at the Paragominas site is a new and promising method called “Nucleation”. Topsoil and cut wood are unevenly distributed simulate a natural landscape and trap rainwater. The wood creates shelters for insects and animals and improves the growing conditions for plants and fungi.

In areas where reforestation has already taken place the regrowth of plants and return of animals is monitored and registered. A pilot projected installed 30 camera traps all over the property to improve the monitoring of jaguars and tapirs.

References:

More Information:

Alumina do Norte do Brasil S.A. (Alunorte)

Hydro creating unfeasible societies in the Brazilian Amazon.